Bread Flour

With a high protein content, bread flour is made from hard wheat and contains a greater amount of gluten than AP, which is made from softer wheat varieties. When worked by hand-kneading or processing with a dough hook in a stand mixer, the gluten is developed and contributes to a chewier consistency, which is desirable in artisan breads. It brings excellent structure to dough's, making it the “underwire bra of the baking world,” says Reid. Bois prefers to use it just for extra-chewy baked goods, like pretzels and bagels, due to its dense and heavy texture

All-purpose flour

White flour milled from hard wheat or a blend of hard and soft wheat. It gives the best results for a variety of products, including some yeast breads, quick breads, cakes, cookies, pastries and noodles. All-purpose flour is usually enriched and may be bleached or unbleached. Bleaching will not affect nutrient value. Different brands will vary in performance. Protein content varies from 8-11 percent

Cake Flour

Similar in protein level to pastry flour (about 8-9%), cake flour is milled to an ultra-fine consistency. It is also traditionally bleached. Bleaching slightly damages the flour’s starches, allowing them to absorb more liquid and rise higher—an ideal quality in lofty cakes.

Best for: Tender cakes, like sponges.

Don’t use for: Cake flour does not produce a good bread product

00 Flour

Ground to extreme fineness, this flour is made from soft wheat varieties, and is frequently used in Italian pastas. The fineness of the grind makes 00 dough easy to roll to extreme thinness (necessary for pasta).

Best for: Pasta, very thin crusts.

Don’t use for: The grind is too fine for successful bread.

Pastry Flour

With a fine texture and lower protein content thanks to soft wheat varieties, pastry flour is the go-to for sweets for many serious bakers. Many commercially-available pastry flours are bleached, although both some millers, like King Arthur and Bob’s Red Mill, offer unbleached pastry flour.

Best for: Pie crusts, breadsticks, pound cakes, muffins.

Don’t use for: The lower amount of gluten means that this flour produces bread with less structural integrity.

Alterna-Flours

Although there are dozens of alternative flours available, we’ll focus here on the most common. When experimenting with new or unfamiliar flours, use tested recipes for the best result.

Spelt

Although spelt is technically a form of wheat, it is often considered in the “alternative” flour guide. It’s an ancient grain, and many with sensitivity to conventional wheat products find they’re able to easier digest spelt. It has a mild nuttiness, natural sweetness, and is relatively easy to work with.

Best for: Breads, pizza crusts, cookies

Don’t use for: No major restrictions.

Barley flour

Barley flour has a natural maltiness in flavor, and is low in gluten. Speck recommends letting doughs and batters made with barley flour (and, actually, all whole grain flours) sit overnight. The rest period will soften the bran, make the product easier to work with, and round out the flavors.

Best for: Barley’s malty-sweet flavor makes it ideal for sweet baked goods and cookies.

Do Not Use For: As with other alterna-flours, 100% barley flour does not make for an ideal bread.

Rice flour

Rice flour has a granular, coarse texture and is gluten-free. Combine it with softer, finer oat flour for a more malleable dough.

Best for: Sponge cakes, noodles, fritters, and tempura batters.

Don’t use for: Breads.

Nut Flours

Made simply from pulverized nuts, these are easy to DIY with a food processor. They can be very powdery, and, of course, contain no gluten. Most common is almond flour, also known as “almond meal.”

Best for: Combining with gluten-containing flours and/or wet ingredients—think cookies and tarts.

Don’t use for: Breads.

Semolina flour:

This is the coarsely ground endosperm of durum wheat. Durum wheat is the hardest variety of the six classes of wheat and has the highest protein content of all wheat. Because of this, it’s ideal for making high-quality pasta and is used by both American and Italian

manufacturers. It’s also used to make couscous in Africa and Latin America, as well as in the U.S. Durum wheat is rarely used to make bread

Durum flour

Is a by-product in the production of semolina. It is usually enriched with four B vitamins and iron, and used to make noodles

Whole wheat flour:

This flour is milled from the entire kernel of wheat. The presence of bran reduces gluten development, therefore, items baked with whole wheat flour tend to be heavier and more dense than those made from enriched flour. Bakers often add additional gluten to counteract this. (one tablespoon/cup of whole wheat flour used

Graham flour:

This also is coarsely ground whole wheat flour. It is named after Dr. Sylvester Graham, the creator of the graham cracker, who advocated the use of whole wheat flour in the early 1800s

Stone ground flour:

This is a type of whole wheat flour that has been milled by coarsely crushing the kernel between two rotating stones. There is no nutritional difference or advantage to milling the flour in this manner

Gluten flour:

Usually milled from spring wheat and has a high protein (40-45 percent), low-starch content. It is used primarily for diabetic breads, or mixed with other non-wheat or low-protein wheat flours to produce a stronger dough structure. Gluten flour improves baking quality and produces high-protein gluten bread.

Wheat Germ flour

Is the inner part (known as the heart) of the wheat kernel. It is very rich in vitamins and minerals and is often added to a variety of baked goods to improve their nutritional value.

Because it contains oil, it is the component of whole wheat flour that makes it more susceptible to rancidity

Cracked wheat

Also known as kibbled wheat, is made by cracking the entire wheat kernel into small pieces, but is not precooked. Cracked wheat can be added to baked goods which adds a crunchy texture and nutty flavor to breads

Crushed wheat flour

Is also a standard whole wheat product. Crushed wheat is made when the milling process first tempers cleaned wheat to a higher moisture level. This softens the kernels before they pass through a set of smooth rollers. The wheat berries are literally flattened and very little flour is released

Bulgur flour

Is made by soaking and cooking the whole wheat kernel, drying it and then removing about 5 percent of the bran and cracking the remaining kernel into small pieces. It is often referred to as par-cooked. It can be reconstituted and added to baked products, salads, desserts, or used as a meat extender

Rolled wheat flour

Is similar to crushed wheat but is thinner and smaller. It is not tempered as long as crushed wheat and the wheat berries are cracked before being rolled. Due to the initial cracking, a little more flour is released. Crushed wheat and rolled wheat are often used in multi-grain and specialty brands

Farina flour

Is coarsely ground endosperm of hard wheat varieties, but not durum. It is the prime ingredient in many hot breakfast cereals. It can also be used to make pasta

White Flour

Taking the whole grain as 100%, white flour is made by sieving out about 25% of the coarser wheat particles. This would include the bran, wheat germ, semolina, and other coarse particles.

The Bread and Flour Regulations require the addition of statutory nutrients to our wheat bread flours other than whole meal. At Doves Farm we do not add any other improvers or enzymes ingredients, bleaches, to our strong flours.

Carefully blended from individual wheat before milling, our white flours are unbleached, unchlorinated and will reward the home baker with an excellent end product. Available in Strong, Plain and Self-Raising.

Self-Raising Flour

This is a plain flour to which self-raising agents have been added. Raising of the dough is caused by carbon dioxide which results from the raising agents, one alkaline (Sodium Bicarbonate) and one acidic (Acid Calcium Phosphate), reacting with water in the recipe. Self Raising flour is used for most cakes, scones, suet pastry and some biscuits.

Gluten Free Flour

Although the gluten can be removed from wheat in a special refining process, gluten free flours are usually made from other cereals (millet, rice, maize or corn) or seeds (buckwheat, chestnuts, chickpeas or grams), or roots (potato, sago and tapioca). Gluten free flours have their own characteristics and do not always react in the same way as wheat flour.

Plain Flour

Milled from softer wheat varieties there should be little gluten or protein in plain flour. It is ideally suited to cooking where the flour must combine well with other ingredients, where short, crumbly texture is required. Use plain flour in biscuits, shortcrust pastry and for sauces. It is possible to use plain flour to make bread but it is unlikely to rise well and will have a close crumbly texture but good flavour

Native Tapioca/cassava starch - Food grade

GRADE 1

Specification:

- Moisture: 13%max

- Starch content: 86% min.

- Ash: 0.1% max.

- Fiber: 0.1% max.

- Whiteness: 95% min

Packing: 25/50kg PP&PE Bag, 25/50kg Paper bag, 850kg Jumbo bag

GRADE 2

Specification:

-Moisture: 14%max

-Starch: 85% min.

-Ash: 0.2% max.

-Fiber: 0.2% max.

- Whiteness:90% min

Packing: 25/50kg PP&PE Bag, 25/50kg Paper bag

Native Tapioca starch - Industrial grade

GRADE 1

Specification:

- Moisture: 15%max

-Starch content: 83 -84%

-Ash: 0.3% max.

-Fiber: 0.3% max.

- Whiteness: 85% min.

Packing: 25/50kg PP&PE Bag

GRADE 2

Specification:

-Moisture: 15%max

-Starch content: 82-83%

-Ash: 0.5% max.

-Fiber: 0.5% max.

- Whiteness: 80% min

Packing: 25/50kg PP&PE Bag

Potato Starch Food Grade

POTATO STARCH SPECIFICATION

TYPICAL ANALYSIS

APPEARANCE : Free flowing dry normal white powder

SMELL & TASTE : Natural neutral

MOISTURE CONTENT : Max 20 %

PH : 7 – 8

ASH : Max 1 %

SULFITE (as SO2) : Max 25ppm

VISCOSITY AT 75.c (2% Solution) : 63 Sacs

FREE ACIDITY : 16.30ml

SOLUBILITY : Insoluble in water with a temperature bellows 50’C and most

COLD WATER SOLUBL : 0.40%

MICROBIOLOGICAL ANALYSIS

T.P.C : Max 10,000/g

YEAST & MOLD : Max 500/g

COLIFORM BACTERIA : Max 10mpn/g

SALMONELLA : Absent 25g

E-COLI : Absent 25g

B.CEREUS : Max 100 cfu/g

PARASITE SEED : NIL

ENTREROCOCCUS : NIL

PHYSICAL POSITION

WEIGHT OF SAMPLE : 1.5KG

DATE OF MANUFECTURE : 25/01/2011

PACKAGED : HDPE bag containing 50kg net,

SHELF LIFE : 5 Years from the date of Manufacture

STORAGE : Keep in Cool and dark place, Protect from direct sun rays, Separated from strong-smelling goods

Potato Starch Industrial Grade

Specifications of Angel Potato Starch

Appearance : White colour free flowing powder

Viscosity of 2% soln in Redwood No.1 Viscometer@75°C : 32 – 34 SEC

Ph of 10% solution : 5-7

Moisture Content : 11 – 13 % Max

% Of Sieve Retention (100 Mesh) : 0.2-0.5%

% Of Total Ash (On Dry Basis) : 0.3-0.5%

Cold Water Solubility% : 0.3-0.4%

Starch Content (On Dry Basis) : 98% MIN

Free Acidity (ml of 0-1 NAOH/100gm) : 20-40ml

Odor : ODOUR LESS

Protein : 0.4-0.5%

Fiber : 0.05-0.10%

Iron PPM : 30-40

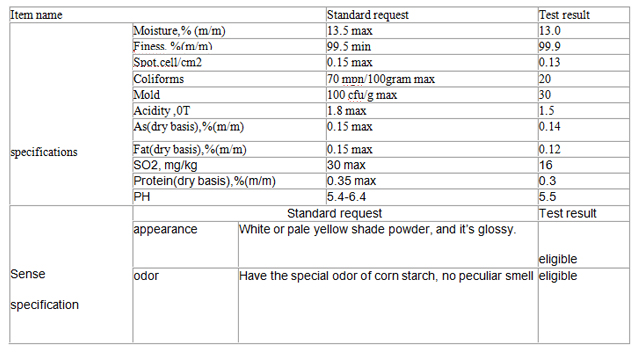

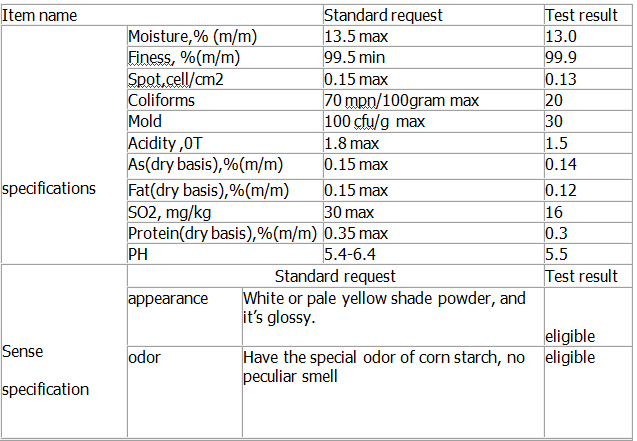

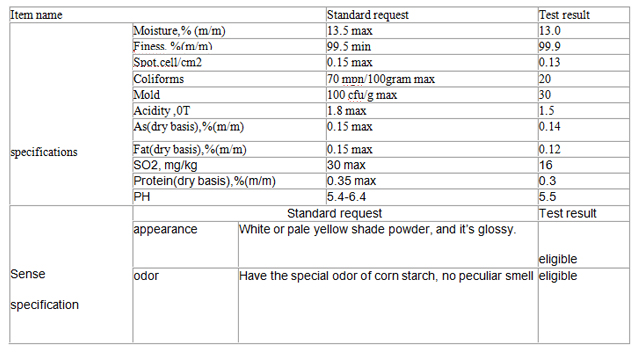

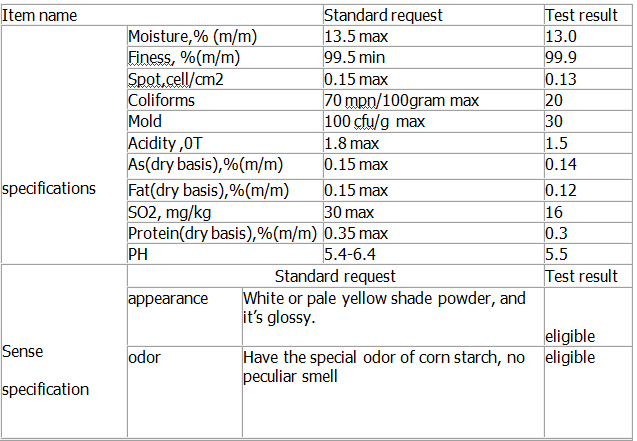

Food Grade Maize Starch Corn Starch Powder Specifications

1.Product introduction of corn starch:

Corn Starch is white and free flowing powder. It is based on corn as raw material, corn powder by soaking, grinding, separating, refining and so on. It is a key material for the manufacture of corn based biochemical products ranging from corn sweeteners to amino acids. Also corn starch itself is one of the important raw materials for food, paper and textile industries

Industrial Grade Corn Starch in Bulk

Introduction:

Corn starch (maize starch ) is powder made through dipping, breaking , separating, refining and drying from corn ,the colour is pure white, it is widely used in food , pharma , textile ,paper industry ,starch deep processing and so on

Applications:

pharmaceutics,papermaking,textile,food,refinesugar,monosodiumglutamate,rubber,plastic,and printing etc.

specification: